GR Supra

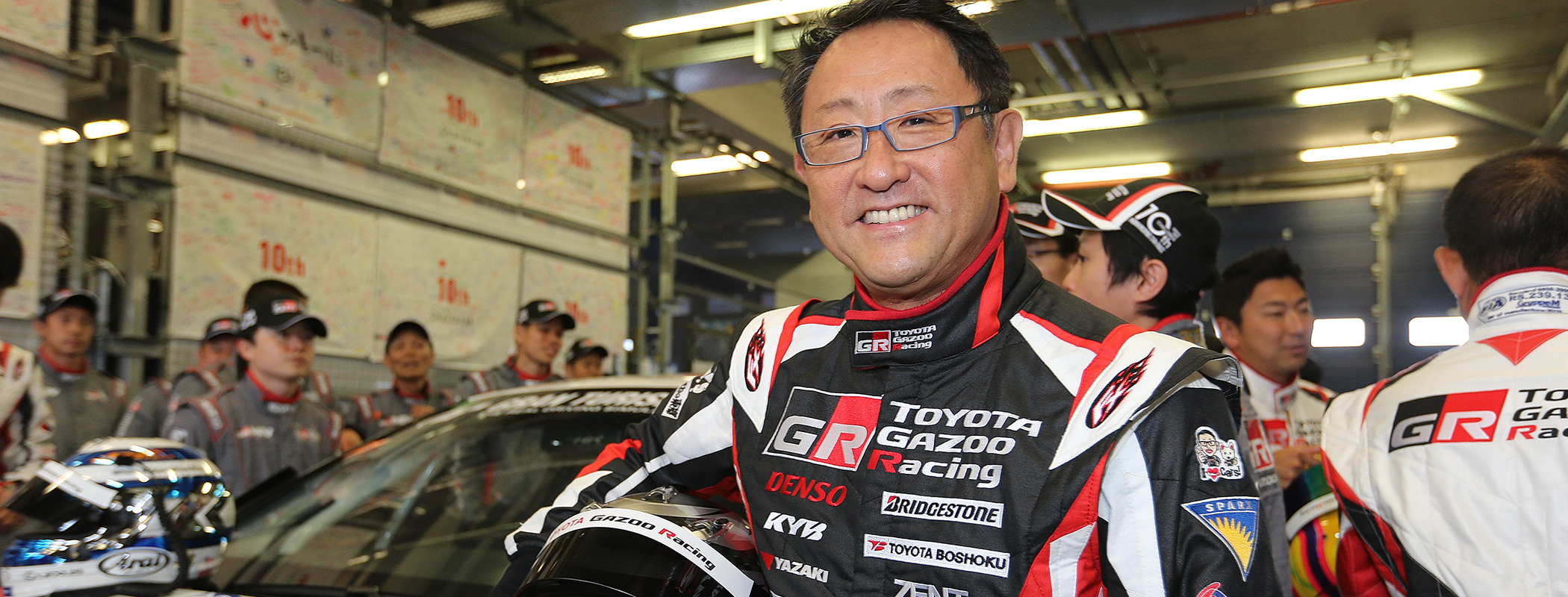

On January 14, 2019, the GR Supra made its first world appearance in the North American International Auto Show. Seventeen years after its production ended in 2002, the Supra really is back. Chairman Akio Toyoda had this to say of the Supra, a vehicle close to his heart:

"I used to ride the Supra as practice to become a master driver, and Hiromu Naruse, who was my teacher at Nürburgring at the time, used it to teach me how to drive.

At the time, we were so frustrated to only be able to drive the already old Supra, no longer in production, while other manufacturers at Nürburgring were driving prototype cars prior to release. It wasn't just the many fans around the world who awaited a revival of the Supra; I too long held a secret dream to bring it back to life. The GR Supra was forged and born at Nürburgring. I can say with confidence that this car offers experiences beyond the mere pleasure of driving it.

I spent a lot of time together with the Supra, and it has become like a 'dear old friend' to me. I am finally seeing my old friend again. I feel like I've finally been reunited with a dear friend I've missed for years.”

The mounting of an inline six-cylinder engine on a front-engine, rear-wheel-drive vehicle has been a feature of every Supra since the birth of the first-generation Supra in 1978. The fifth-generation GR Supra has, of course, also inherited this DNA. The Supra saga that all the fans have been waiting for is picking up where it left off.

to Nürburgring

- About Nürburgring

- We continue to embrace the challenges of Nürburgring.

Our drive to make “ever-better” cars is never-ending.

Nürburgring is one of the world’s most difficult courses and one that incorporates the characteristics of roads worldwide with 300 meters of elevation change and more than 170 curves of all sizes. More than the course’s difficulty, the distinguishing characteristic of the 24 Hours Nürburgring is that it requires the team to overcome what is often described as the world’s harshest track for 24 hours straight. During the race, the team must instantly identify the causes of any problems or accidents and take recovery actions as quickly as possible.

In 2018, TOYOTA GAZOO Racing undertook a major challenge. The team switched the racecar from the LEXUS RC to the LEXUS LC. In addition to the challenge of compressing the vehicle development process, which usually takes four or five years, into a single year, the team had to incorporate advanced development technologies into the LC with a view toward their use in future mass-production models. The development process was brutal, and during the shakedown in Japan, drivers criticized the vehicle as "far from the level of a racecar.

"Following testing in Japan and practical tests on-site at Nürburgring, the team was finally prepared for the first day of qualifying session. The car placed 34th overall but it was not sufficient to put a smile on the driver’s face. He remained concerned about whether the car could complete 24 hours on the track. Driver, mechanics, and engineers gathered after the end of the first day to pursue fundamental solutions to the vehicle’s remaining issues. They then tested the resulting improvements on the second day of qualifying session.

As a result of their efforts, the team was able to start from the No. 31 grid in the final race. Immediately after the start of the final race, the LC had a racing accident with another car. Even after that, TOYOTA GAZOO Racing encountered a series of problems. However the quick and reliable actions of the team members, namely drivers, mechanics, and engineers allowed the car to complete the 24-hour race without further incident for a 96th-place finish, enough to put the vehicle in first place in the SP-Pro Class. It may not have been the most satisfying result, but in exchange the team learned many lessons. Mechanics learned that if a driver can depress the accelerator pedal with peace of mind here, that trust will resonate on roads worldwide. Engineers gained extensive knowledge under the harshest conditions in the world by putting future-oriented advanced development technologies to the test at Nürburgring, and in doing so they discovered a new path that leads to the development of mass-production models. There is no end to the goals that TOYOTA GAZOO Racing embraced in its efforts to compete at Nürburgring: our drive to make “ever-better” cars and to foster the development of the people who will support that process.