TEST

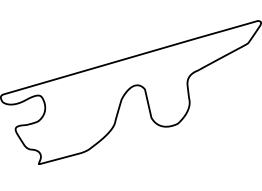

Course:Fuji Speedway

2018 Reports - Vol.1 Domestic tests

On January 12, 2018, at the Tokyo Auto Salon 2018, TOYOTA GAZOO Racing announced both the model and team structure with which they would enter the 2018 “24 Hours of Nürburgring”. Behind the scenes, car-making was progressing steadily.

Discussions regarding the specifications of the race car began in June, after the previous 24 Hours of Nürburgring. By the time TOYOTA GAZOO Racing had announced its participation for 2018, the vehicle had already undergone numerous circuit tests.

With regard to selecting the race car, the RC—which had been entered since 2015—had achieved success in just three years of participation; for this reason, if TOYOTA GAZOO Racing's aim was to achieve a leading position in the race, one option was to further develop the RC. However, TOYOTA GAZOO Racing has aimed at “refining people, refining cars” throughout the 24 Hours of Nürburgring; escaping the limitations attached to production vehicles has enabled the company to make ideal cars from scratch, assimilate knowledge acquired at the races, and feed this back into the development of other Toyota and Lexus models. For this reason, TOYOTA GAZOO Racing chose to incorporate into the LC advanced developmental technologies that it wished to use in future production cars, and make improvements to the vehicle.

Toyota employee Kazuyoshi Ogata, who is lead engineer for the 24 Hours of Nürburgring and also works on development of GR products, explained his role at the race: “Due to cost and legal restrictions, when developing production cars it frequently happens that we cannot try out the technologies we want. Development of race cars enables us to attempt making cars that are one step further advanced than production cars—and this is significant. Of course, during development we encounter various challenges; however, it is the mission of the engineers to overcome them. In my opinion, what is important is that we establish a positive cycle whereby we utilize the knowledge acquired through racing in the development of production cars.”

After the decision was made to enter the LC, the team set out development goals in accordance with the race regulations. These included vehicle weight, and engine, body, and suspension specifications.

Lightening the body was one of the team’s focal points. Weight has an effect on the acceleration, turning, and stopping of a vehicle—in other words, on every aspect of its basic performance. The team therefore removed parts that were not required for the race, swapped out standard components for those made with different materials, and considered how the lighter weight influenced the front-rear balance of vehicle.

With regard to the engine, race regulations imposed an upper limit on power output. Consequently, the team sought to improve fuel and environmental performance while at the same time optimizing torque. The goal was not simply to finish the race as fast as possible—the vehicle specifications were drawn up with one eye on how they might benefit the development of production cars.

In early October 2017, mechanics from Toyota's Advanced Technical Skills Institute completed the race car. Thus far, everything had gone better than expected.

However, during shakedown testing, lead driver Takeshi Tsuchiya commented: “My impression of the car is that it works; that it is capable of moving. But improving the car from the present situation will be extremely difficult.”

Evaluation drivers from the Advanced Technical Skills Institute, who normally perform driving evaluations of production cars, were also severe in their criticism of the vehicle: “There’s no point testing it—it’s far from a car.”

Chief mechanic Toshiyuki Sekiya expressed his desire to improve the car: “This time, we built the LC from scratch. It is a fact that Hiromu Naruse, who initiated Toyota’s participation in the 24 Hours of Nürburgring, experienced the ‘pains of birth’ while developing the LFA. However, while I feel the pressure of the project, it is rewarding at the same time. We are incorporating a large number of new technological elements, so there are a number of challenges for us. However, our goal is to make a car of which drivers will say: ‘Let me drive one more lap,’ or ‘Is it already time to pit?’ In order to achieve this, it is vital that we link the empirical rules of the mechanics, the data of the engineers, and the tactile feedback of the drivers. We cannot be buckled under the harsh criticisms from the drivers.”

This year, there has been a change in the pace at which the car is being developed. Takamitsu Matsui, one of the drivers, has seen a significant difference: “Compared to last year, the team have responded extremely well to driver feedback; when making changes, the results of the modifications and the level of development is extremely impressive; in all honesty, the car has improved with astonishing speed. In addition, communication between drivers, engineers, and mechanics has become very smooth.”

Takeshi Tsuchiya, who also works as an engineer, has also sensed that the team has grown: “I believe that we have established a positive cycle of rapid development: (1) looking for the root cause of a problem, (2) fixing the problem, (3) improving the car and identifying the correct path forwards. It is difficult to express in words how remarkable it is. However, it is now natural for results to be immediate, and the quality—whether something is right or not—has also progressed to a high degree. I think we are now approaching the level of prestigious Japanese racing teams.”

Lead engineer Ogata said: “Although I am designer, I didn’t interfere in the design for this project. I expected each team member to be able to demonstrate his or her capabilities, so I worked as a ‘translator’ between drivers, engineers, and mechanics, and aimed to remove the barriers between the various fields to an unprecedented degree. I took care to achieve a positive balance between three elements: the empirical rules of the mechanics, who have real experience in manufacturing; the data of the engineers; and the feedback of the drivers, who have actually driven the vehicle. I believe that this has resulted in accelerated decision-making and a faster pace of development.”

Regardless of which section team members were assigned to, the fact that they all shared the same aim of making “ever-better” cars was key to perfecting the vehicle. In this way, domestic tests revealed that car-making was progressing smoothly in the run up to the 24 Hours of Nürburgring.

However, when the LC was driven in the 24 Hours of Nürburgring, the team was forced to make an entirely different evaluation.