Text/Martin Sharp Translation/Keiko Ito

Photos/Naoki Kobayashi, Hiroyuki Takii, Tsuyoshi Fukue, TOYOTA, RALLY PLUS

The Yaris WRC overcome the problems it faced in its debut year

to become the fastest rally car of the current generation,

and to propel TOYOTA GAZOO Racing to the manufacturers’ title—but how did it manage to do this?

The TOYOTA GAZOO Racing World Rally Team won the WRC manufacturers’ championship in 2018, in only the second year of its return to the motorsport—a spectacular achievement. It was back in 1999 that Toyota last secured the title, when Toyota Team Europe (TTE) won with the Corolla WRC.

The Yaris WRC played a major role in Toyota’s first triumph in 19 years—but what is the secret behind its astonishing speed?

Overhauling the cooling system,

which had limited the Yaris WRC’s performance in the early rounds

There is no longer any need to expound on the team’s capacity to adapt or on its togetherness. Rather, let us focus on how it secured its first title and, to begin with, let us look back on 17 years of competition to identify the reasons for the car’s initial underperformance.

The biggest miscalculation when it came to developing the Yaris WRC was, almost certainly, that the team underestimated the importance of cooling during high-temperature rallies.

According to TOYOTA GAZOO Racing chief engineer Tom Fowler, “We completely misread Rally México in 2017.” At that time, Fowler was using a scale model in wind tunnel tests, but was having difficulties understanding the cooling system; the team had not yet completed its work on computational fluid dynamics. As a result, in the high altitudes, high temperatures, and low speeds of Rally Mexico, the Yaris WRC’s lack of cooling was exposed.

Fowler notes ruefully: “It was not simply a problem with the design or structure of the rally car.”

“We had achieved strong results in Monte Carlo and Sweden, so we prioritized performance in the run up to Mexico,” he says. “Looking back now, if I were to pinpoint our key mistake, it is that we should have made reliability our top priority. We knew that Rally Mexico would be hot and driven at low speeds, and of course we understood that we would have to complete the rally. However, we chose a setup that prioritized performance, and this had an impact on the car’s cooling capabilities.”

For the 2018 season, the Yaris WRC lined up at Monte Carlo with improved aerodynamic parts, including a new front bumper and fenders. The team had modified the shape of the openings in the front bumper in order to increase cooling performance, and it had added new canards in order to achieve the balance it was seeking. This shifted the aerodynamic balance slightly to the front of the car.

If the 2017 Rally México was a “complete failure, ” then Fowler sees the 2018 Rally México as “a complete failure in parts.”

“From 2017 to 2018, we had been improving the cooling system. In 2018, however, the temperatures in Mexico were 10 degrees higher than the previous year. Although the improvements we had made had some effect, they were by no means sufficient.”

In 2018, the second most important rally in terms of cooling was Rally of Turkey. The team therefore prepared a package of updates that improved the cooling capacity of the Yaris WRC by approximately 20 percent, and introduced them in Turkey. It is clear from the results that the updates were a success—while the team’s rivals suffered a succession of mechanical issues, the Yaris WRC secured a one-two finish.

Fowler notes that the team did not have to use a development joker for the cooling system it introduced at Turkey: “Of the cooling system components, only the intercooler has to be official approved; for this reason, we were free to change other parts such as the radiators and ducts. We decided to improve cooling efficiency by using a Denso-made radiator and newly designed ducts—everything went as planned, and we were able to achieve an outstanding result.”

- Chief engineer Tom Fowler was in charge of developing the Yaris WRC from before it made its debut. Using his experiences from the last two years , he intends to further improve the performance of the rally car in 2019.

Modifying the front-rear aerodynamic balance to improve handling

12Canards were added to the front of the car in order to achieve the appropriate front-rear aerodynamic balance with the massive rear wing; the shape of the bumper was also slightly altered with the aim of improving cooling efficiency. Yet the 2018 Yaris WRC featured few major changes when compared to the 2017 model, and this can be seen as evidence that the car’s development had been on the right track.

3A total of four canards—two each on either side of the car—improve aerodynamics at the front of the Yaris WRC

4Winglets were added to the upper part of the front fenders; a vacuum is created beneath the winglets that draws air away from the fenders

5The front fenders have a complex shape: the upper parts extract hot air from the engine room, while the lower parts work to remove air from the wheel well

6The rear wing astonished the team’s rivals when it made its debut; the winglets that jut out on either side also contribute to generating downforce

7There are openings located high up on the rear diffuser—this design is being copied by the team’s rivals

8Sweeping up toward the rear tires, the side sills have an aerodynamic design

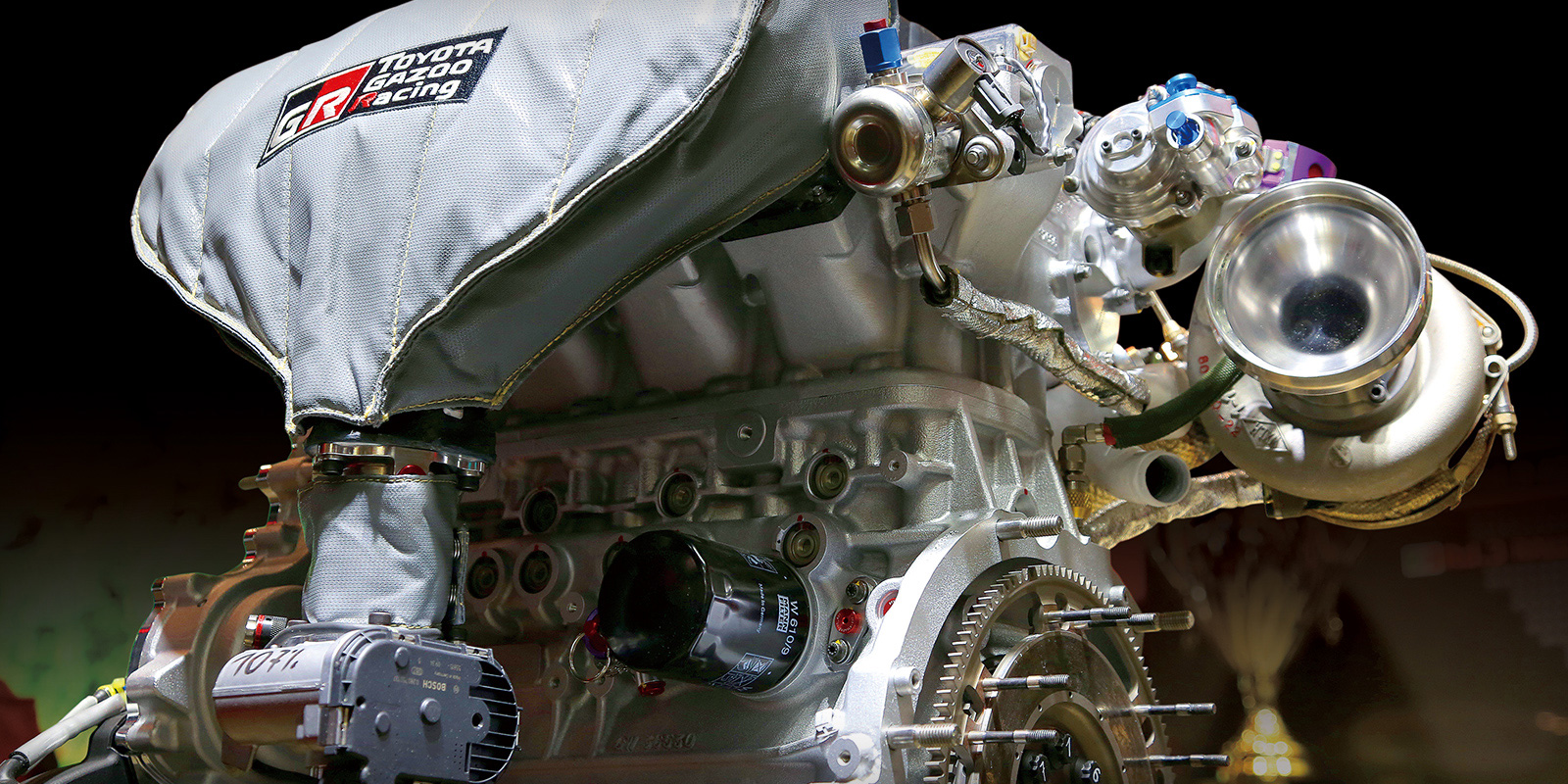

Developing the heart of the Yaris WRC at TMG

- WRC engine project manager Tokuo Aoki is in charge of overseeing all aspects of engine development at TMG, including technological elements

If cooling presented the biggest problem, where do the strengths of the Yaris WRC lie?

The Yaris WRC’s biggest strength is without doubt its engine. Development and production of the engine is carried out by Toyota Motorsport GmbH (TMG), which is located in Cologne, Germany. The engine is then fitted to the car by TMG engineers at the team’s base in Puuppola, Finland.

An improved engine was fitted for the opening round of the 2018 season, then further updates were added in Round 8, Rally Finland. Tokuo Aoki, WRC engine project manager at TMG, explains:

“We prioritized performance and drivability. We believe it is important to link driver feedback with what they feel. It is our role to interpret what they want from an engineering standpoint. In this respect, I think we succeeded in taking development as a whole in the right direction and increasing the power of the engine.

“The updates resulted in no loss of engine power, and a significant increase in torque. But it does not necessarily follow that the drivability of the engine improved. Drivability is about what the drivers want before the engine reaches maximum torque. The characteristics we desire in our engine is that it will produce more torque and power at all times—there is no benefit in pursuing power alone, and then ending up with an engine that is peaky and hard to control. For this reason, the key to this updated engine was raising the baseline of the torque curve. This resulted in improvements that astonished even ourselves.”

The engine that was introduced at Rally Finland is known as the Spec-5 engine, and featured an updated camshaft. Ott Tänak used this engine to propel him to victory with incredible speed. His rivals could only look on enviously at the pure pace of the Yaris WRC; in fact, the car was so fast that they referred to the rally as the “Finnish Grand Prix.”

Each team was permitted to use three engine jokers during the 2018 season, and the TOYOTA GAZOO Racing team used its second of the season in Turkey . But this was a software and not a hardware update, and its goal was to improve throttle response. Apparently, there is a special “out of session” regulation that enables engine jokers to be used to improve software. This made the Spec-5 engine easier to handle, and contributed to Tänak’s superb victory.

The Yaris WRC had overcome the issues with its cooling system, featured outstanding chassis balance, and was equipped with an engine that continued to be developed tirelessly. As a result, Toyota was able to win the manufacturers’ championship in only the second year of its return to the WRC. This was reward for the supreme efforts of the engineers, who demonstrated an abundance of experience and capacity for learning.

Updates introduced at Rally Finland lead to improved cooling in the second half of the season

The Yaris WRC undergoes maintenance at Rally GB. The cooling system is positioned low down on the front section; the radiators are situated on either side of the three cores; the intercooler lies in the center; a cooling fan is located on the engine room-side, discharging hot air through the top of the hood.

1The air outlets on top of the hood are positioned toward the middle; in theory, the outlets direct hot air to either side of body, but a balance has to be struck with the shape of the ducts

2he engine is positioned low, close to the cabin, and tilted backwards; the fact that it fits comfortably into the compact Yaris engine room shows how small the engine is. The ducts are ordinarily covered up—as in picture 3—and cannot be seen. Air is taken in through the spaces around the Toyota emblem.

All heavy parts are positioned near the floor of the car to lower its center of gravity

1All superfluous parts have been removed from the driver’s seat; switches are located on the steering wheel itself, and gears are shifted using carbon paddles

2Visible in front of the sturdily built roll cage is the rear suspension strut tower; it clearly shows how long the suspension stroke of a World Rally car is

3The switches and monitors positioned above the center tunnel face the co-driver; the low position of these controls is a consequence of trying to lower the center of gravity as much as possible

4WRC regulations require shock absorption pads to be installed between the seat and car body in order to protect the driver and co-driver; the interior of the doors also contain expanded foam

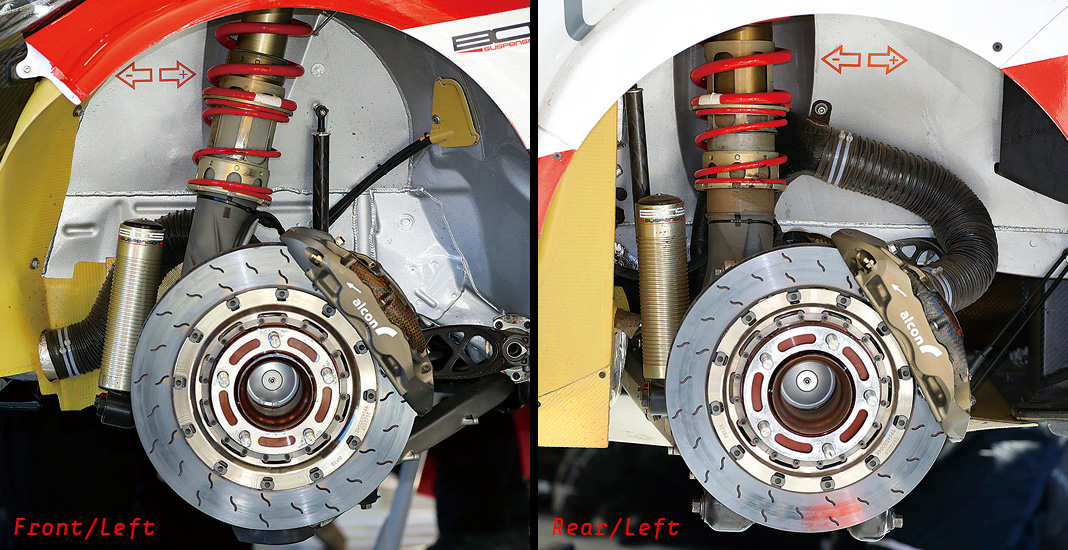

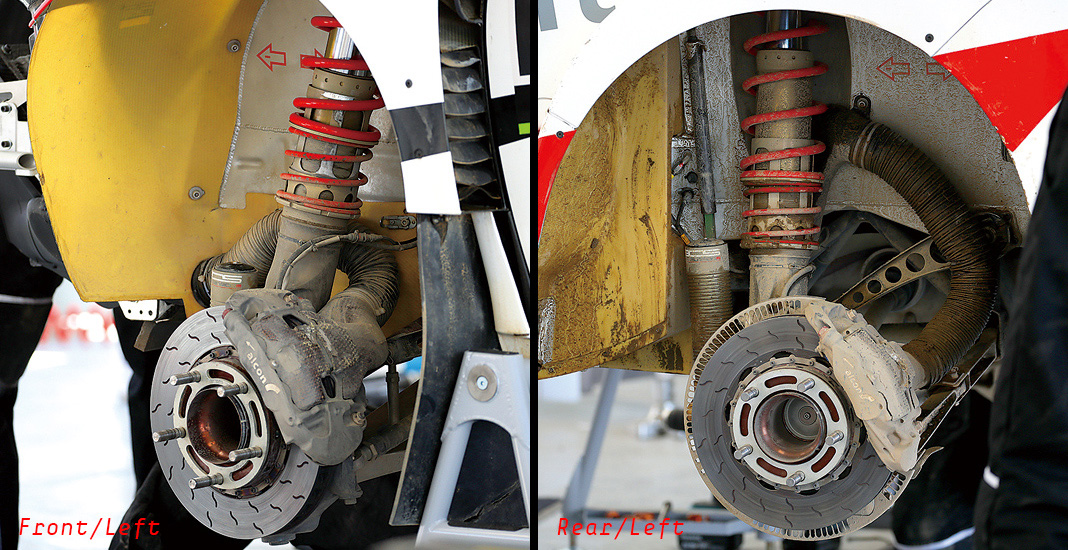

The 2018 Yaris WRC continues to use BOS dampers

The photos show the suspension as specced for Round 9 in Germany. On tarmac, the car height is lowered for greater stability; however, since the car is required to jump at high speeds on occasion, some suspension stroke is required

The photos show the suspension as specced for Round 3 in Mexico. While a long suspension stroke is critical on gravel, it is vital that the car strikes a good balance between handling and suspension. The caliper cooling duct can be seen on the front.